The Science

Our Three Step Process

Step 1

The powder coating process begins with a complete cleaning to remove any surface contaminants such as corrosion, dust or oils. The cleaning process can consist of sand blasting, chemical cleaning, or a combination of the two.

Step 2

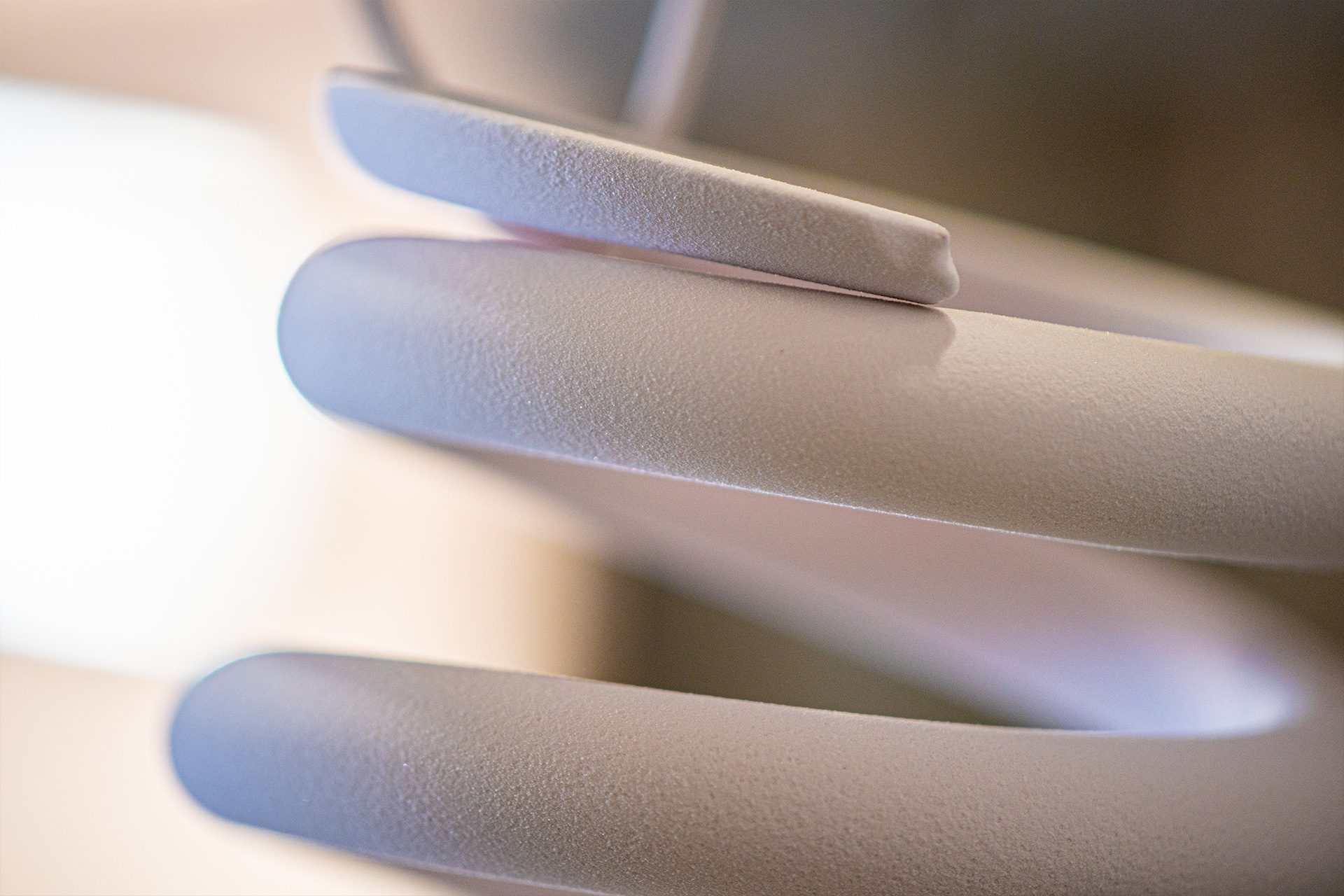

After cleaning, the work piece is moved to the enclosed and ventilated spray booth. A slight negative electrical charge is applied to the work piece and powder is applied through a specialized nozzle that imparts a positive charge to the paint particles. The positively charged powder is attracted to the negatively charged work piece and a smooth, even coat of powder is produced.

Step 3

After powder, the workpiece is moved to the curing oven. Normally the powders cure at 200°C (390°F) in 10 minutes. The curing schedule could vary according to the manufacturer’s specifications.

Environmentally Friendly

We utilize DuBois Chemicals to further reduce the environmental impact of powder coating and the chemical cleaning process.

Latest Projects

Get a Quote For Your Project

Contact Us

St Helens OR 97051